Because the Planet Deserves Better

Because the Planet Deserves Better

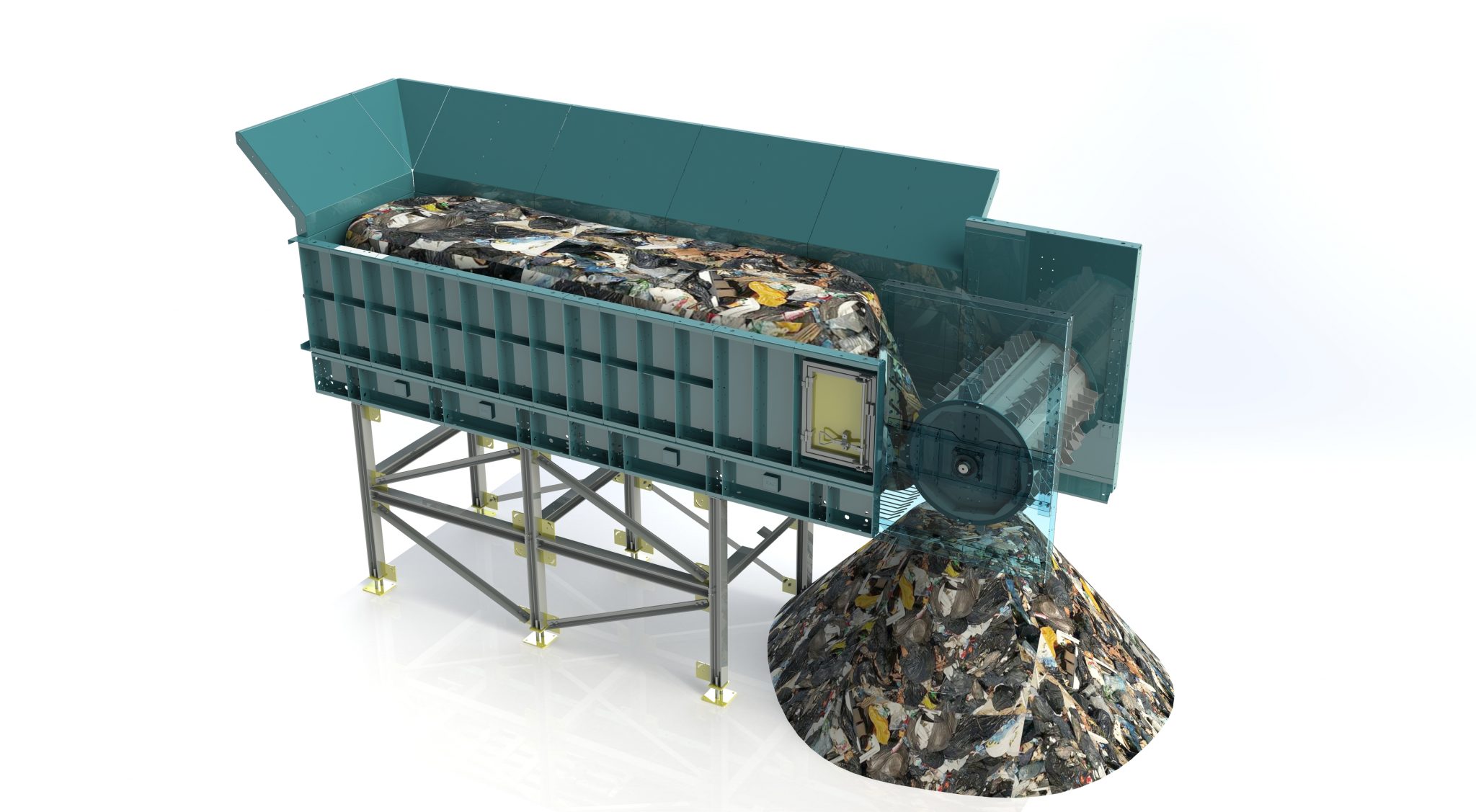

CONVEYING EQUIPMENT

A walking floor machine in waste facilities is a heavy-duty conveying system designed to move bulk materials using a series of hydraulically driven, segmented floor panels. These panels operate in a coordinated back-and-forth motion: they move together to advance material forward, then retract individually to reset without pulling the load back. This cyclical movement provides a smooth, continuous, and controlled transport of materials such as municipal solid waste, biomass, RDF, sawdust, plastics, and other loose or bulky materials. Walking floor systems are especially useful in areas where belt or chain conveyors are impractical, such as feeding shredders, loading bunkers, managing storage pits, or unloading trailers. Their robust hydraulic design allows them to handle heavy loads, resist jamming, and operate reliably even with irregular or moisture-rich waste. They also offer flexible speed control, low maintenance requirements, and safe handling of large material volumes within modern waste-processing facilities.

| UNIT | DYT1600 | DYT2000 | DYT2600 | |

| Power | kW | 7,5 | 7,5 | 15 |

| Feeding Speed | m/min | 0-1,1 Adjustable | 0-1,1 Adjustable | 0-1,1 Adjustable |

| Length | mm | 6000-7000-8000-9000-10000-12000 | ||

| Width | mm | 1600 | 2000 | 2600 |

| Height | mm | 1130-2260-3390 | ||

| Capacity (h:1130) (t/hour) | Household Waste | 40 | 50 | 65 |

| ATY | 20 | 30 | 35 | |

| Organic | 70 | 90 | 110 | |

| Biomass | 15 | 25 | 30 | |

| Machine Weight | ton | 4,2 | 4,8 | 6,3 |

| Feeding | Bucket / Overhead Crane | |||

Adjustable Speed

Easy Feeding

Anti-Winding Design

Continuous Dosing